Why Use Glass Grinders for Material Removal

Glass grinders offer numerous benefits that make them indispensable tools in various industries. Here, we explore the advantages of using glass grinders, highlighting their key benefits.

Enhanced Precision

Glass grinders provide unparalleled precision, crucial for intricate and detailed work. This is particularly beneficial in fields like lampworking and jewelry making, where fine details are essential.

Smooth Finishes

Achieving smooth, flawless finishes is a significant advantage of glass grinders. Whether finishing edges, polishing surfaces, or creating seamless transitions, the quality of the finish is consistently high, enhancing the aesthetic appeal of the final product.

Consistent Results

Designed to produce consistent and repeatable results, glass grinders are ideal for applications requiring precise and accurate components. This uniformity is especially important in scientific research where strict quality standards must be met.

Versatility

These tools are highly versatile, suitable for a wide range of tasks, from removing large chunks of material to fine-detail finishing. This makes them invaluable in various applications, such as glass art, lampworking, and scientific research.

Cost and Time Efficiency

While glass grinders may have a higher initial investment, they offer long-term cost savings and time efficiency. Their precision and speed reduce overall time and labor, resulting in more efficient workflows and higher productivity.

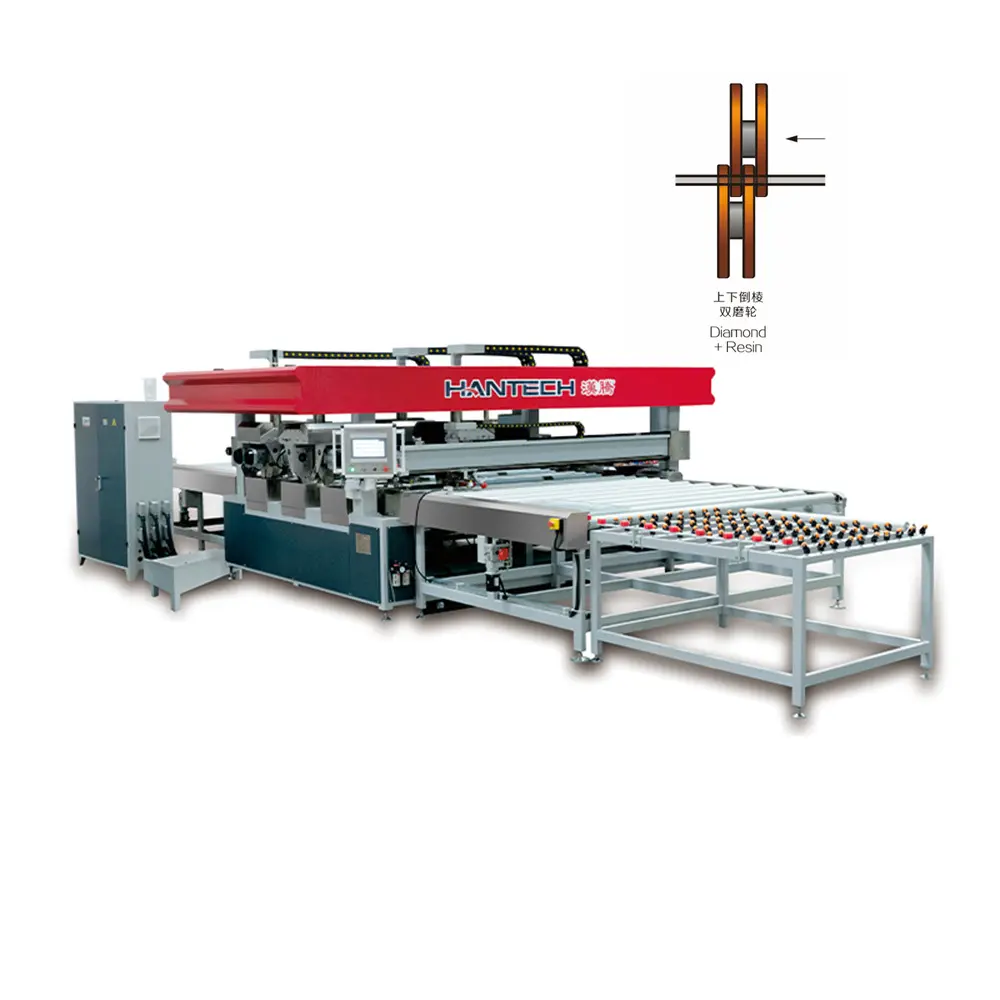

Glass Grinders in Industry

Glass grinders play a crucial role in various industrial sectors, enhancing precision, reducing material waste, and improving operational efficiency. They excel with flat lap grinders for consistent, high-precision finishes and diamond cup wheels for rapid material removal on flat and curved surfaces. These tools speed up production processes and contribute to higher quality outputs, essential for maintaining customer satisfaction.

Water-based systems and eco-friendly abrasives further enhance sustainability by reducing noise and dust pollution. The integration of advanced technologies such as IoT and AI allows for real-time data monitoring and predictive maintenance, streamlining processes and improving performance.

How Glass Grinders Improve Precision

Glass grinders significantly enhance precision in material removal processes, particularly for ultra-thin or intricate glass parts. Advanced grinding technologies and precise control through automation ensure consistent surface finishes and minimize the risk of cracks or fractures. They can adapt to varying design complexities, ensuring uniformity across detailed components. Real-time analytics and machine learning optimize grinding processes, reducing waste and improving overall product quality. Predictive models adjust parameters in real-time to prevent deviations, while anomaly detection identifies and addresses issues early.

Best Practices for Using Glass Grinders

To use glass grinders effectively, follow these best practices:

- Selection and Preparation: Start with lower grit for specialized types of glass.

- Cooling and Lubrication: Use water with a mild detergent to prevent heat damage and extend the grinding wheel.

- Maintenance: Clean and maintain the wheel regularly to ensure optimal performance.

- Safety: Wear eye protection, use vibration-dampening gloves, and work in well-ventilated areas.

Automated grinders offer advanced precision and efficiency but require careful consideration of initial costs and specialized training.

Glass Grinders vs. Other Abrasive Tools

Glass grinders and other abrasive tools excel in different applications. Glass grinders provide precision and fine finishes for complex shapes and delicate materials, ideal for tasks like polishing glass edges or creating intricate designs. Sandblasters, on the other hand, are faster and more effective for large-scale projects, removing old paint, sealants, or coatings quickly. Glass grinders generate less dust and are safer, while sandblasters offer faster surface preparation.

Environmental and Economic Benefits of Sustainable Practices

Glass grinders contribute to sustainable practices by:

- Reducing Waste: Precise material removal minimizes dust and waste.

- Lower Energy Costs: More efficient operations lead to lower utility bills and reduced carbon emissions.

- Cost Savings in Cleanup: Less frequent cleaning is required, saving time and resources.

- Government Incentives: Tax credits, subsidies, and grants make the transition to sustainable practices more financially viable.

- Enhanced Environmental Footprint: Cleaner air and reduced pollution contribute to a safer work environment.

FAQs Related to Glass Grinders

What are the key benefits of using glass grinders?

Glass grinders offer enhanced precision, smooth finishes, consistent results, versatility, and cost and time efficiency. They are particularly useful in industries like glass art, lampworking, and scientific research.How do glass grinders improve precision in material removal processes?

Glass grinders use advanced grinding technologies and precise control through automation to ensure consistent surface finishes. They can handle varying design complexities and adapt to ensure uniformity across detailed components, minimizing the risk of cracks or fractures.What are some best practices for using glass grinders?

Best practices include selecting the appropriate grit based on the type of glass, using water with a mild detergent to prevent heat damage, maintaining the grinding wheel regularly, and ensuring safety by wearing protective gear.How do glass grinders compare to other abrasive tools like sandblasters?

Glass grinders are best for precision and fine finishes, ideal for complex shapes and delicate materials, while sandblasters are faster for large-scale projects. Glass grinders generate less dust and are safer, whereas sandblasters offer faster surface preparation.What are the environmental and economic benefits of using sustainable practices with glass grinders?

Sustainable practices with glass grinders reduce waste, lower energy costs, minimize cleanup, and provide government incentives. They also contribute to a cleaner environment and enhanced productivity, such as reducing carbon emissions and dust pollution.